Engineering

Superior Engineering Services.

When it comes to engineering experience and expertise in the extrusion industry, you have come to the right place.

Decades of working within many different industries has given us experience solving a wide variety of problems and prepared us to be able to help you. Your extrusion project’s configuration and complexity is something we can handle.

To aid in the process, our engineers use state of the art 3D CAD/CFD (Computer Flow Simulation), FEA (Finite Element Analysis), and SolidWorks programs to custom design any of the following extrusion tooling products:

- Crossheads

- Inlines & Spiderless Inlines

- Rotary Heads

- Custom Heads

- Deflectors

- Tips & Dies

- Accessories

- Clamps

- Swing Gates

- Flanges

- Breaker Plates

Our Engineers are Here for You

Our staff is available to answer any question you have regarding your extrusion tooling needs.

We employ a staff of world-class engineers experienced in a variety of extrusion fields. Design Engineers utilize the most state-of-the-art computerized programs to assure functional performance of all extrusion tooling manufactured. A number of our patented and proprietary tooling features are integrated into a variety of applications to improve process control.

In addition, Guill engineers are available to visit manufacturing facilities throughout the world to evaluate production methods with the intent to offer process improvement recommendations.

Engineering Capabilities

Tools to Get the Job Done.

We are committed to continuous improvement and investing in the knowledge and technology to always be on the leading edge of extrusion tooling.

3D Computer-aided Design, also known as CAD or MCAD (mechanical computer-aided design) is defined as the use of computer systems to aid in the creation, modification, analysis, or optimization of a design. The benefits of CAD include, but are not limited to improvement in productivity in the design process, shorter lead times, greater design analysis and fewer design errors through computer elimination of errors in design, drafting, and documentation.

Additionally, flexibility in design leads to easy modification per client request which result in higher efficiency across the board.

Computer Aided Design and Manufacturing (CAD/CAM) is a software that we use to both design and manufacture products. CAD is responsible for the design and documentation of your product, while CAM takes your designs and manufactures a physical replica of your product.

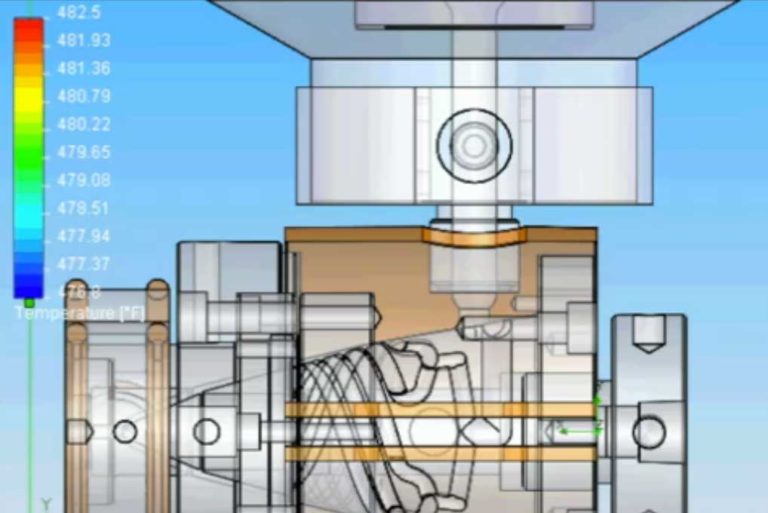

Computational Fluid Dynamics (CFD) analysis simulates how liquids and gases pass through or around objects. The use of computer software to simulate these variables can save time and funds which otherwise would be allocated to a real life physical test.

Guill uses Fluid Dynamics software from COSMOSFloWorks in conjunction with SolidWorks.

Guill uses CAMWorks to wipe out hours of complex programming with CNC, thanks to Automatic Feature Recognition (AFR) defining machinable features while the Technology Database defines operations to automatically create toolpaths at the click of a button. CAMWorks uses SolidWorks technology to create toolpaths that ensure the part you create is the part you designed.

Finite Element Analysis (FEA) is a computerized method used to predict how a product reacts to real-world forces such as vibration, heat, fluid flow, and other physical effects. FEA helps predict the behavior of products affected by many physical effects, including: mechanical stress, mechanical vibration, fatigue, motion, heat transfer, fluid flow, electrostatics, and plastic injection molding.

Guill’s use of SolidWorks flow simulation allows leveraging of numerous programs as well as being an effective tool for communicating ideas. The same solid model geometry can be used for fluid flow, stress, and thermal analysis, as well as CNC programs and even for rendering designs for marketing purposes.

Guill uses Teksoft CAD software to model all custom designs. Teksoft holds the distinction of introducing the first PC-based CAD software, and continues to offer the most innovative technology for producing cutting edge products.

Engineering Resources

Some Help Along the Way.

Wouldn’t it be nice to have the tools you need in one place? We think so.