Machining & Fabricating Manufacturing Services

We Offer More

Than Just

Extrusion Tooling

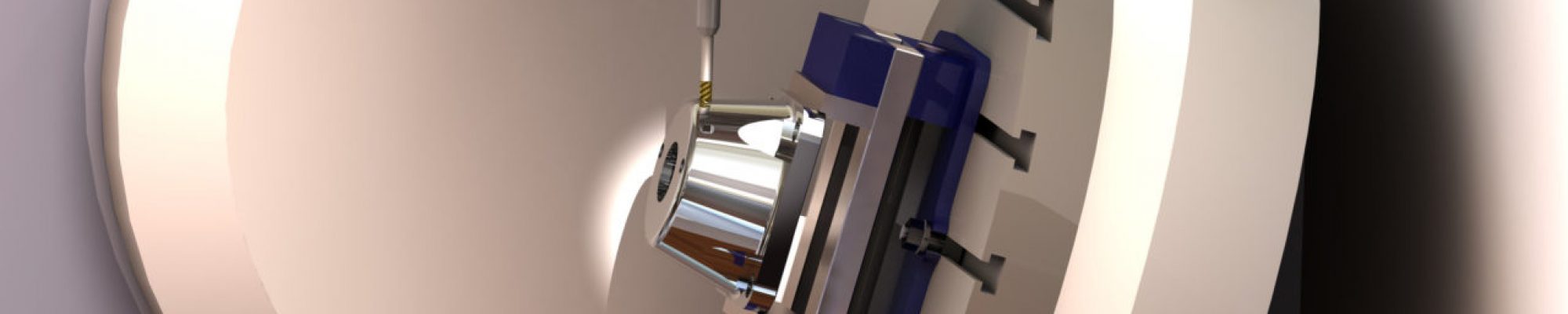

Advanced Machining & Fabricating Capabilities

Look no further for your precision machining and fabrication needs. We have been providing tooling for the defense industry for nearly 60 years. We have a highly-skilled team of expert machinists and engineers trained in the latest CAD, CAM, CFD, and FEA programs.

Not only are we experts in extrusion tooling, but our expert manufacturing team can provide you with a comprehensive offering to fulfill all your machining needs. The more we understand about your business, the better we can serve you. We would love to partner with you and your company.

Send Your Drawing & Requirements

Industries Served

Certifications

- ISO 9001:2015 Certfied by NQA

- Defense:

- AS9100D Certified by NQA – Aerospace

- MIL-I-45208A – Inspection System

- MIL-STD-45662A – Calibration System

- JCP Certified – Government Contracting

- ITAR Registered – Export Compliant

- NIST SP800-171 Compliant – Cyber Security

Download Our Facilities List

Our Services

- 5-Axis machining centers

- Full-wire EDM capabilities with a .008” hole popper

- High-precision machining

- Machining of super alloys/exotic metals to close tolerances

CNC Milling

Our CNC milling machines can take on even the most challenging parts and tooling to keep your equipment running efficiently and with precision.

CNC Turning

The precision of CNC turning allows for a quicker production that meets our rigorous standards no matter the complexity of the parts you need.

Multi-Axis Machining

Our multi-axis machines allow us to produce a variety of complex designs and sizes with efficiency and accuracy.

Prototype Machining

Prototype machining and rapid manufacturing enable engineering to develop and innovate with the ability to respond and modify parts when required.

Super Alloys

Our experience with super alloys and materials benefits our clients when they need a new solution to a difficult tooling problem.

Wire EDM

Wire EDM eliminates the force put on parts. This protects intricate and fragile tooling as well as granting higher tolerances and accuracy.

Machining Range

Our machining capabilities include 5-Axis machining centers and wire EDM capabilities ranging from:

- Small hole machining to .008 inches diameter

- Machining material measuring 15 inches cubed

Explore Our Capabilities

CNC Turning Centers

Daewoo Puma 350L

35 HP/26″ swing x 82″

Fanuc Series 18-T

Conversational Control

Doosan Puma 480

CNC Lathe

60 HP/25.6″ Max Turn Dia.

Fanuc Series 211-TB Control

DMG Mori NLX2500SY/700

Twin Spindle Mill/Turn CNC Lathe

Chuck Sizes:

Primary-10.0”, Secondary-8.0”

24.7 HP / 10.0” Max. Turn Dia.

12 Station Tool Turret for Both Sides

Celos Conversational Control

Mori Seiki NL200Y

Mill/Turn CNC Lathe

15 HP Spindle Drive

5 HP Rotary Tool Drive

x+y+z Drives

14″ Dia X 20″ Liner Travel

Mitsubishi MSX-850 Control

2) Mazak QTS 200M

Mill/Turn CNC Lathe

25 HP, 8.0” Dia. Chuck

Max. Turn Dia. = 10.0”

12 Station Tool Turret

Mazatrol Smart Control

Mazak QT 250HP KY

CNC Lathe

25 HP / 10” Chuck

Mazatrol PC Fusion Control

Mazak QT 20HP KY

CNC Lathe

20 HP / 10” Chuck

Mazatrol T. Control

Yama Seiki GS-3300a

CNC Lathe

25 HP / 12” chuck

Max. Turn Dia. = 12.0”

12 Station Tool Turret

Fanuc Control

Machining Centers

Mori Seiki NMV5000DCG

5 Axis Machining Center

x Travel 28.7”

y Travel 20.1”

z Travel 25.1”

b Travel +160° to -180°

c Travel +/-360°

20.0” Dia. Table

Max. Dia. Capacity 27.6”

60 Tool Changer

DMG Mori DMU 50

5 Axis Machining Center

x Travel 19.7”

y Travel 17.7”

z Travel 15.7”

b Travel -5° to +110°

c Travel +/-360°

Max. Dia. Capacity 21.3”

30 Tool Changer

Matsuura 560V

Machining Center

20” x 40” x 22” with 4th axis

30 Tool Changer

Mori Seiki NV5000 A1

Machining Center

40” x 20” x 20” with 4th axis

30 Tool Changer

Matsuura V1000

Machining Center

20” x 20” x 40” with 4th axis

30 Tool Changer

Matsuura MC760 V

Machining Center

20” x 20” x 40” with 4th axis

30 Tool Changer

EDM Machines

Agie-Chamilles Hole Popper

As small as .008 Start Hole

x, y, z 11.8” x 7.8” x 11.8”

Work Pc. Capacity 19.6” x 15.7” x 9.5”

Agie (Ram Type)

Mondo 2

Die Sink 12” x 14” x 20”

Elec. z Axis

14” Color Graphic Control

Charmilles 440 (Wire Type)

Robofil 5 axis E.D.M.

x Travel 21.650”

y Travel 13.770”

u Travel 21.650”

v Travel 13.770”

z Travel 15.750”

(2) Charmilles 330F (Wire Type)

Robofil 5 axis E.D.M.

x Travel 15.750”

y Travel 11.800”

z Travel 15.750”

u Travel 19.680”

Charmilles 230 (Wire Type)

Robofil 5 axis E.D.M.

x Travel 13.770”

y Travel 8.660”

u Travel 13.770”

v Travel 8.660”

z Travel 8.660”

Manual Machines

Engine Lathes

Bridgeport Vertical Mills

Horizontal Mills

Precision Grinding Machines

JMC 1000H ID-OD Grinder

20″ D x 40″ L

Chevalier ID-OD Grinders

14″ D x 40″ L

Okamoto Surface Grinder

12″ x 24″ with 8″ Rotary Attachment

Surface Grinders

up to 8″ x 28″

Inspection Equipment

Nikon MM-40

Measuring Microscope

Hexagon One CMM

Axis Capacity

X=25″, Y=36″, Z=20″

Brown & Sharp Tessa Microhite 600

Height Gauge – 24″ Height Capacity

Brown & Sharp Hite-Tronic

Height Gauge – 36″ Height Capacity

Taylor Hobson

Profilometer Surtronic 3

Surface Finish Gauge

Electronic Height Gages

Granite Surface Plates

Optical Comparators

Rockwell Hardness Testers