Materials Testing

Rheology Lab

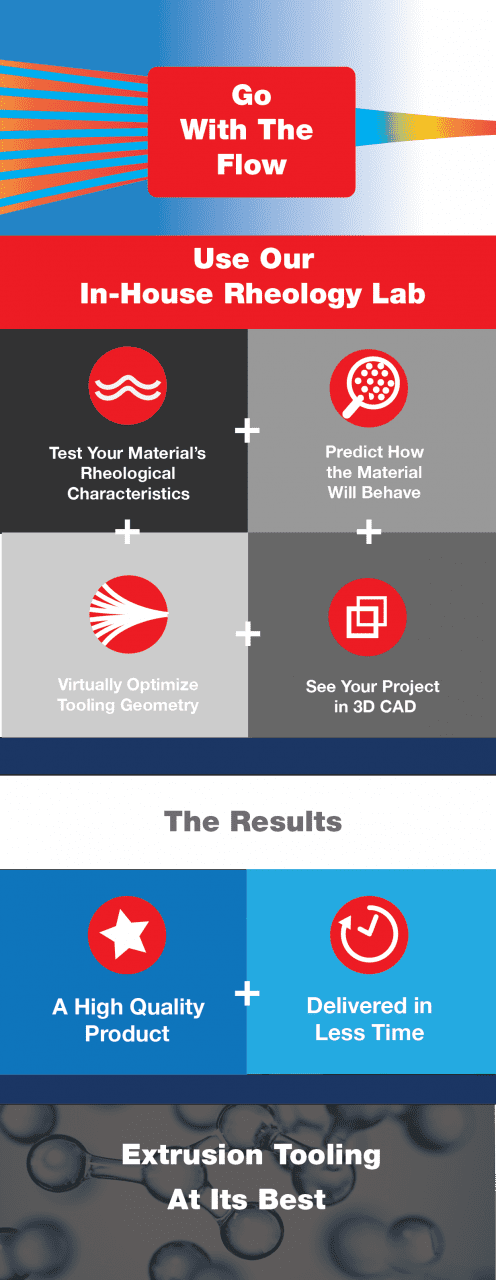

Our rheology lab allows us to measure the flow characteristics of a plastic. This lets us better predict how your material will flow through our extrusion dies before they’re even made. This simulation greatly reduces the number of physical reworks needed, as the tooling has a greater chance of producing a quality product right away.

Other companies typically outsource their testing. With our own in-house lab, the turnaround on test results is quicker, reducing delays during the design process and offering better control over the testing parameters. What does this mean for our customers? A higher quality product delivered on time.

Extrusion Expertise Is Here For You

Rheology Equipment

Rotational Rheometer

- Quickly generate visco-elastic data for polymer melts

- Precisely capture the polymer melt properties for accurate simulation of the flow of polymer through an extrusion die

- Accurate simulation greatly reduces the number of physical reworks necessary because the tooling is much closer to producing a good product out of the box

- In-house testing of polymers greatly speeds up turnaround on test results, resulting in less delay during the design process

- In-house testing gives better control over the process and test parameters

- Test temperature ranges between ambient and 300˚C

Scanning Calorimeter

- Characterizes thermal properties of a polymer sample

- Can be used to find properties such as crystallization temperature, glass transition temperature, and head capacity of the sample

- Thermal properties allow for much more accurate simulation of the polymer flow through the extrusion tooling, allowing the simulation of shear heating and hot and cold spots in the flow area

Thermal Conductivity Meter

- Used to determine the thermal conductivity of the polymer sample across a range of temperatures

- Adds to the accuracy of a thermally dependent flow simulation