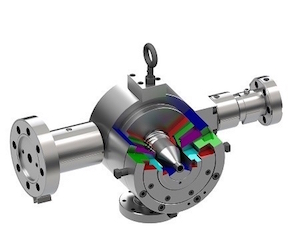

Guill Tool introduces Series 824, a co-extrusion crosshead designed for irrigation tubing with an emitter tool. Manufactured from stainless steel, this new crosshead features balanced flow design with spiral technology that improves flow characteristics at all extruder speeds. Dual feed ports provide concentric compound flow, while the splits flow from one extruder to feed the inside and outside layers via a manifold assembly. Series 824 is adaptable to all popular extruders on the market currently.

Capacities include a max. die ID of 1.875″, max core OD of 1.250″, max. tip OD of 1.500″ and max. emitter tool OD of 30mm (1.18″). The Series 824 design allows the emitter insertion tool to pass completely through the crosshead ID. Gum space adjustment is performed with die nut rotation, while the Guill 2-stage clamping mechanism allows easier concentricity adjustment. Quick-change tooling and a tool kit for disassembly and re-assembly are provided with the unit.

Bill Conley, sales manager for Guill, comments, “On this project, the customer challenged us with an application that required precise placement and bonding of preformed emitters within the extruded tubing without melting them in the crosshead. It was also necessary to process either a low-cost ABA layer construction or single-layer construction within the same unit.”

With the Series 824, the customer realized cost reductions, better quality, less scrap and more uptime in their process. The Guill cool-tube design prevented the emitter from melting in the head and the overall unit mechanics allowed more rapid and easier changeover from a co-extrusion to a single layer.

On this project, Guill also supplied the customer the company’s extrusion tool cart, which facilitates easy alignment and tool changes. The removable cart swing gates stay free from accumulated process fluids, while the adjustable height means the cart is compatible with virtually any extruder model. Thermal isolation in the design keeps heat in the head, not the cart.