The 500 Series

Our Water Cooled Rubber & Silicone

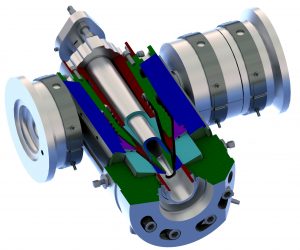

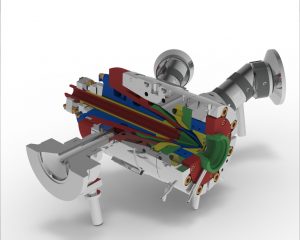

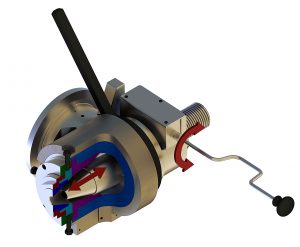

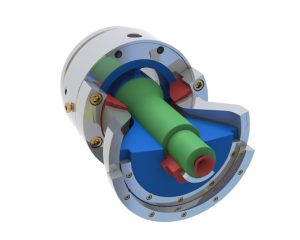

The 500 series is designed specifically for the flow characteristics and unique processing challenges of elastomeric compounds. One of the key features engineered by Guill is the mechanically adjusted gum space (MAGS) adjustment system. This system allows the operator to make an easier, quicker adjustment from a single point using a common socket wrench, eliminating the struggle of multiple nuts and bolts.

The hardware-free and patented cam lock design of the 500 series reduces time spent unbolting and re-securing fasteners for disassembly and reassembly. Only half of a rotation of a cam nut if required to loosen and and automatically extract the deflector from the head body. Also, with no undercuts on the deflector, there are no material hang-ups when extracting the deflector, allowing for faster and easier cleaning and changeover.

The 500 series also features the latest Center-Stage concentricity adjustment system, reducing pressure on the tooling, allowing easier and more precise concentricity adjustments without loosening the face bolts. Easy-Out inserts for the adjusting bolts allow simple replacement of locked or damaged adjusting bolts, further saving on repair downtime.

The 500 series crosshead with MAGS gum space adjustment is a drop-in replacement on most existing NRM lines. This crosshead design can be adapted to fit any extruder design or line layout.

All crossheads supplied by Guill are furnished with a tool kit for assembly and disassembly as well as a detailed operator’s instruction manual. The engineering team at Guill will gladly assist users in the implementation and operation of the 500 series crosshead.

| Model | Core Diameter inches | millimeters |

Max Die inches | millimeters |

||

|---|---|---|---|---|

| 520 | 0.437 in. | 11.00 mm | 0.500 in. | 12.70 mm |

| 523 | 0.718 in. | 18.20 mm | 1.000 in. | 25.40 mm |

| 525 | 1.125 in. | 28.50 mm | 1.500 in. | 38.10 mm |

| 527 | 2.375 in. | 60.30 mm | 3.000 in. | 76.20 mm |