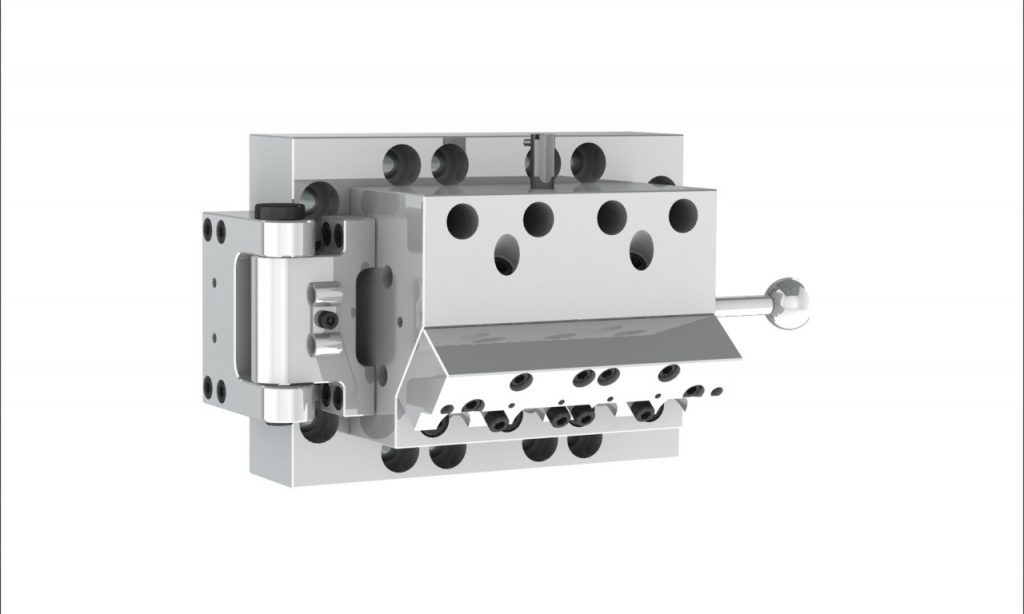

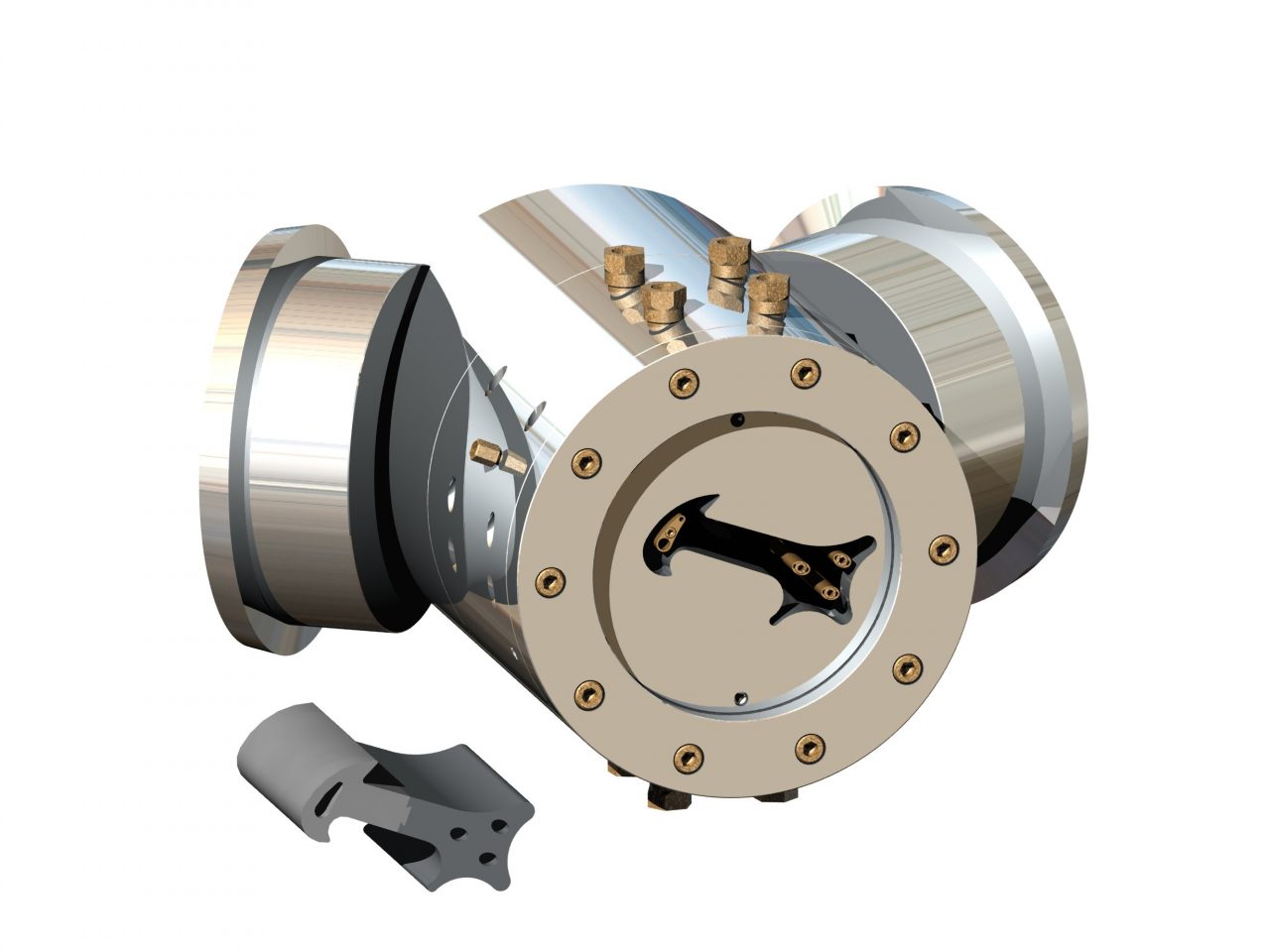

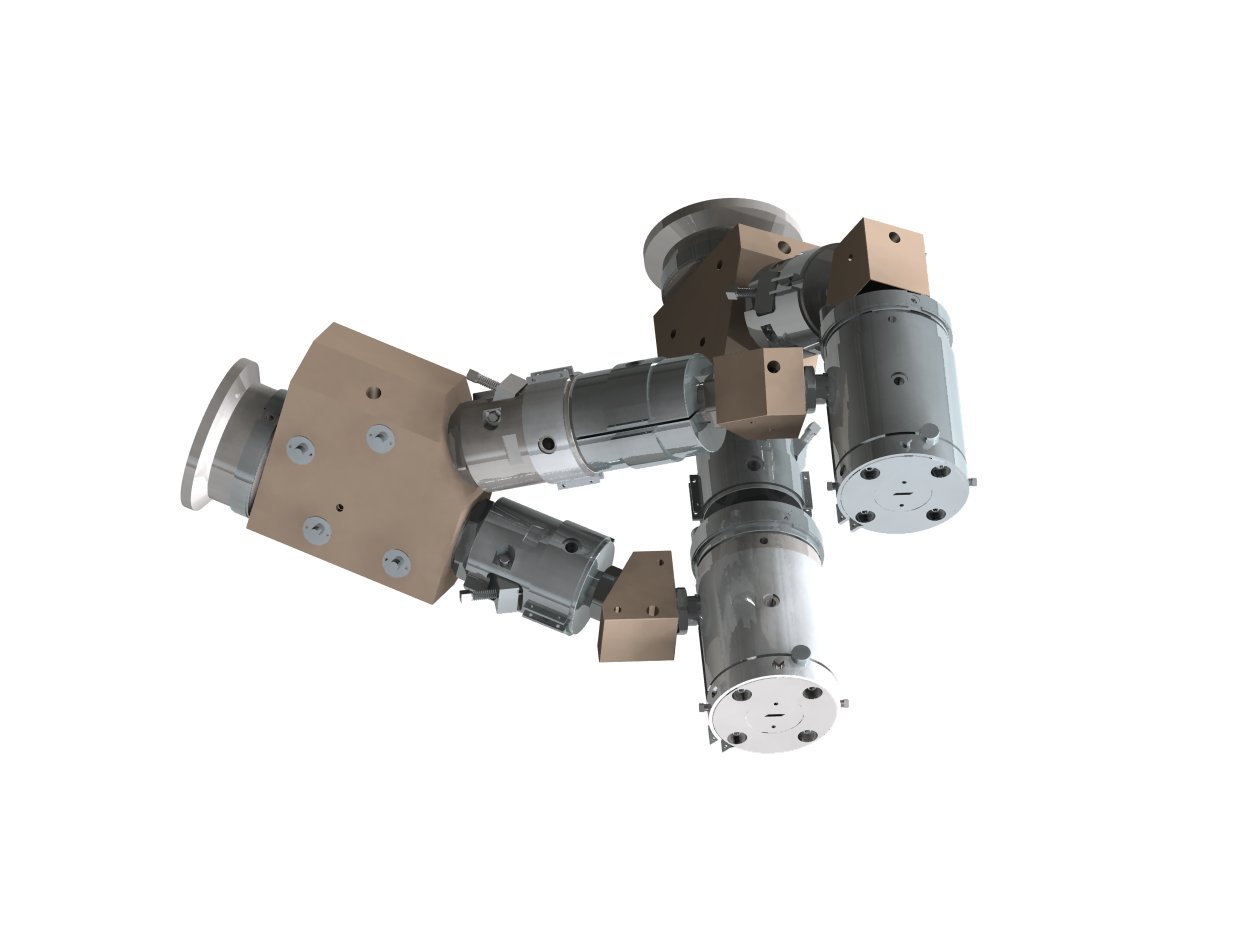

Our company manufactures top quality pelletizing extrusion tooling, defined by an unparalleled attention to detail. Pelletizing extruders function to produce polymer or composite pellets in a seamless continuous process.

Each Guill pelletizing extruder’s balanced flow design utilizes a multiple strand extrusion process that substantially improves production capacity. From animal feed to PVC pellets or specialty polymers, our tooling produces the finest end products at a fraction of the cost of our competitors.