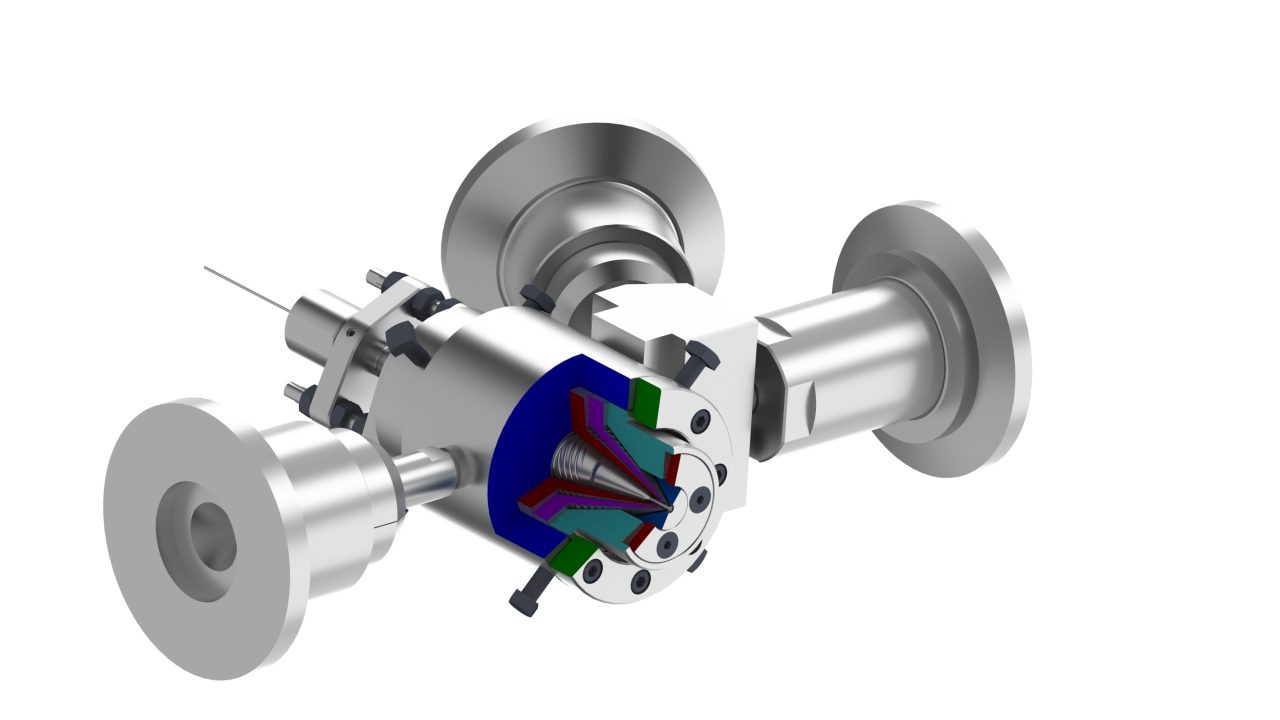

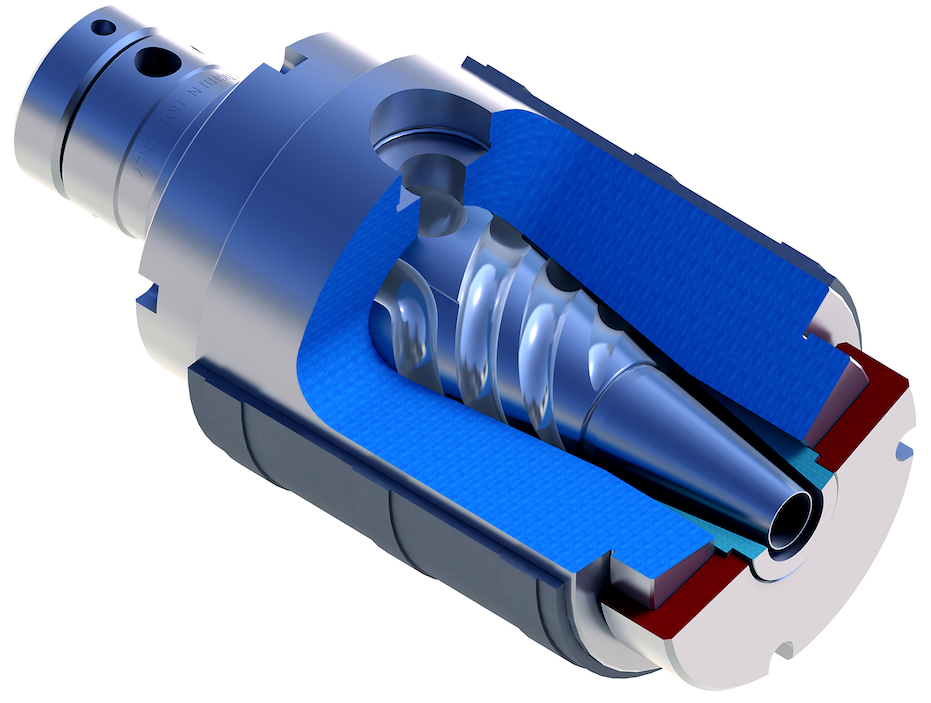

Our extrusion Single and Twin Screw tooling is designed to balance the melt flow necessary for the demands of pharmaceutical applications. Knowing that short residence time, temperature control and ease of cleaning are high priorities when developing pharmaceuticals, we have developed crossheads, inlines and rotary head that will fill that criteria. You will find many options within our vast product line that will help meet your requirements.

Pellets

Creating consistently sized pellets made of polymer, animal feed, or wood is made easy using our custom tooling. Producing pellets through extrusion yields numerous advantages over using a pellet mill, eliminating the presence of harmful microbes and often mitigating the need for binders in animal feed, and allowing more control of pellet density than traditional milling.