Series

Our Product Line

We have organized our extrusion tools into series by categories for specific applications and processes.

This overview is to give you an idea of how versatile our line is. But don’t worry about choosing the correct Series for your End Product. That’s the job of our Sales Engineers.

Let us know what your requirements and specs are by using one of our many Data Process Worksheets available on our site and they will work with you to develop the proper tooling for the job.

100 – Pelletizing Heads

If you need Single or Multi-Strand extrusion tooling with or without Multi-Layer capabilities, we have a solution for your project.

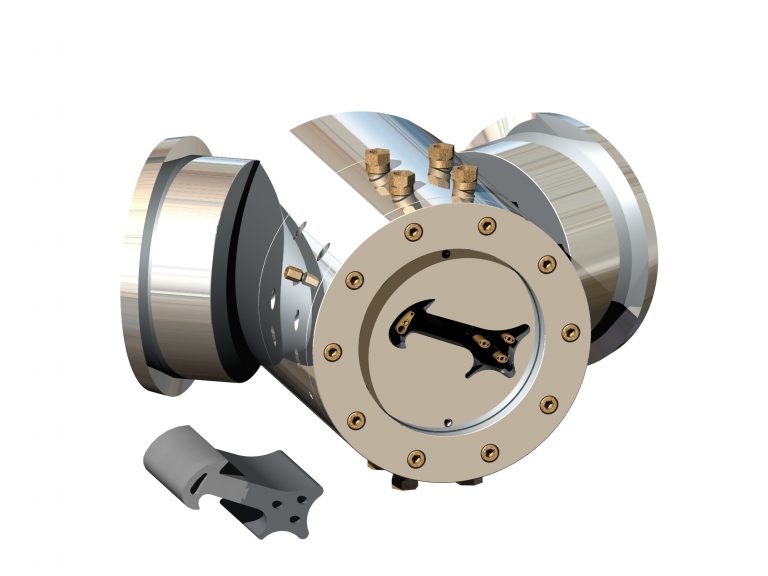

1000 – Blow Molding Dies

Our 1000 Series are available as Single Layer, Co-Extrusion, or Triple Extrusion with fixed or adjustable concentricity die adjustments.

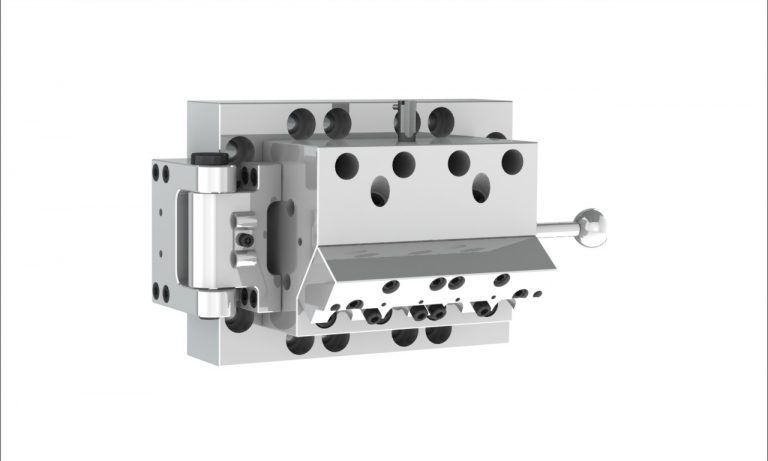

200 – Profile Dies

Our heads are designed to resolve problems with polymer variations when producing profile and seals of various shapes and sizes.

2000 – Large Diameter Dies

Our 2000 Series is our range of large diameter Inline heads, and features a low volume flow, heated core pin, and can be expanded to output multi layer products.

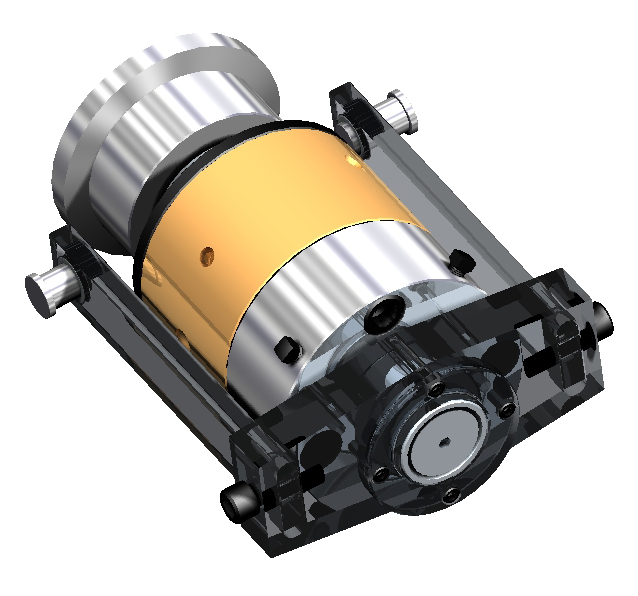

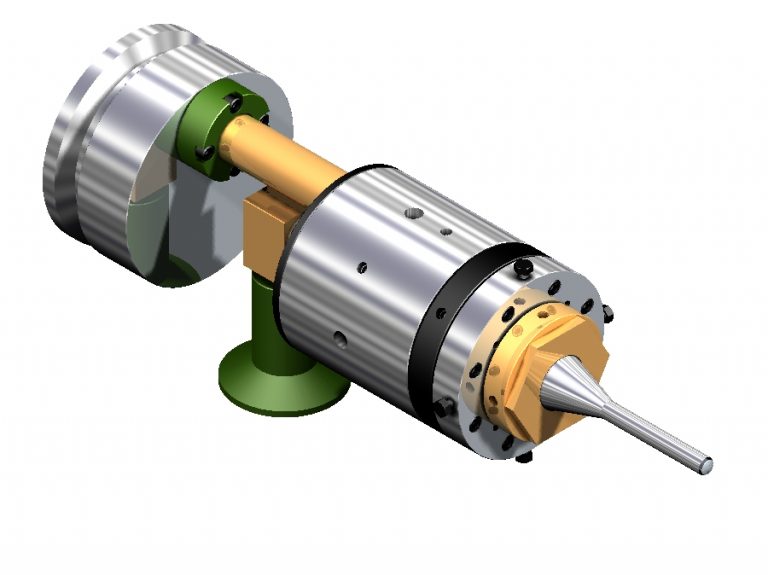

300 – Rotary Heads

We have developed a patented Rotary Head design intended to be used in a variety of applications to increase tube wall strength.

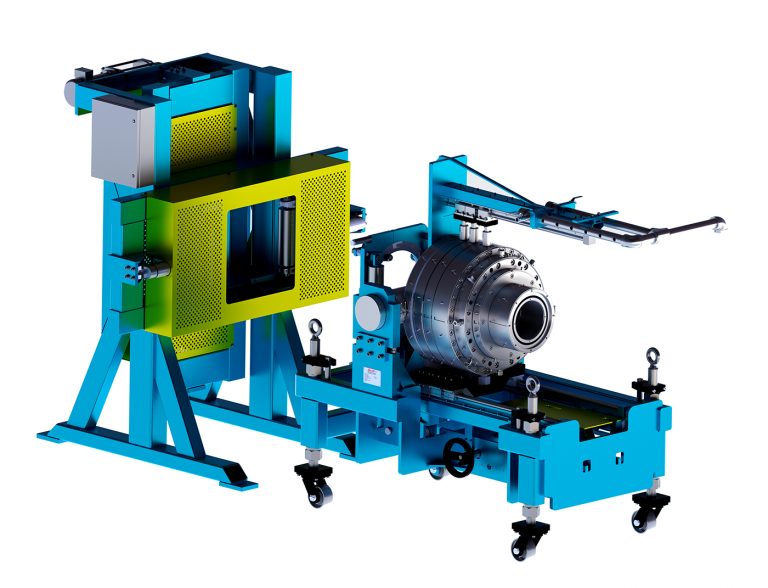

400 – Corrugated Hose & Pipe

The 400 Series offers a host of benefits for OEMs, as well as for automotive and medical applications wide variety of corrugated equipment and molds.

500 – Rubber & Silicone

The 500 series is designed specifically for the flow characteristics and unique processing challenges of elastomeric compounds.

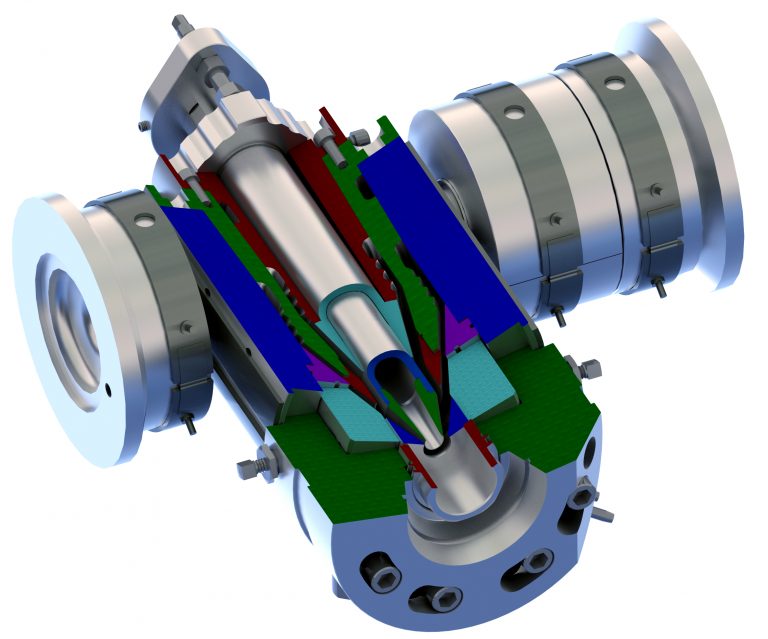

600 – Flexible Crosshead

The 600 Series Crossheads offer flexibility in design & extruder orientation with split balanced flow.

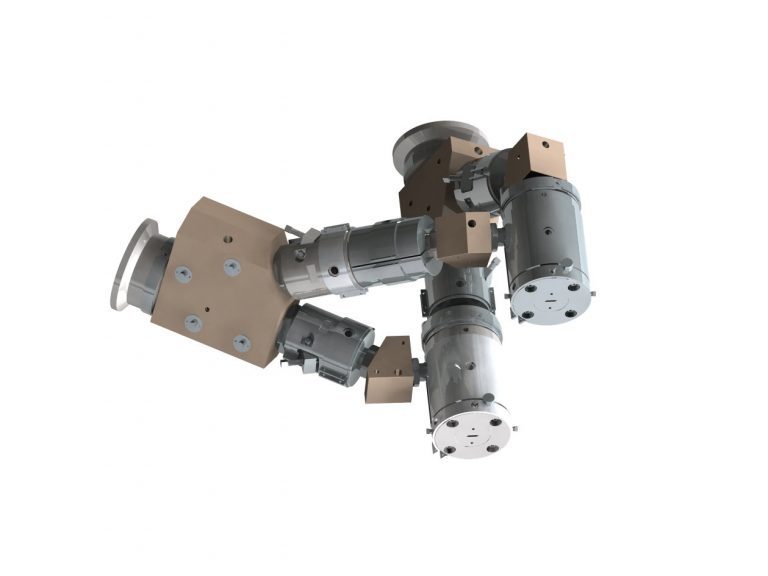

700 – Standard Crosshead

Our 700 Series crosshead is fully adjustable and accepts existing tooling. It beats the competition in both price & performance.

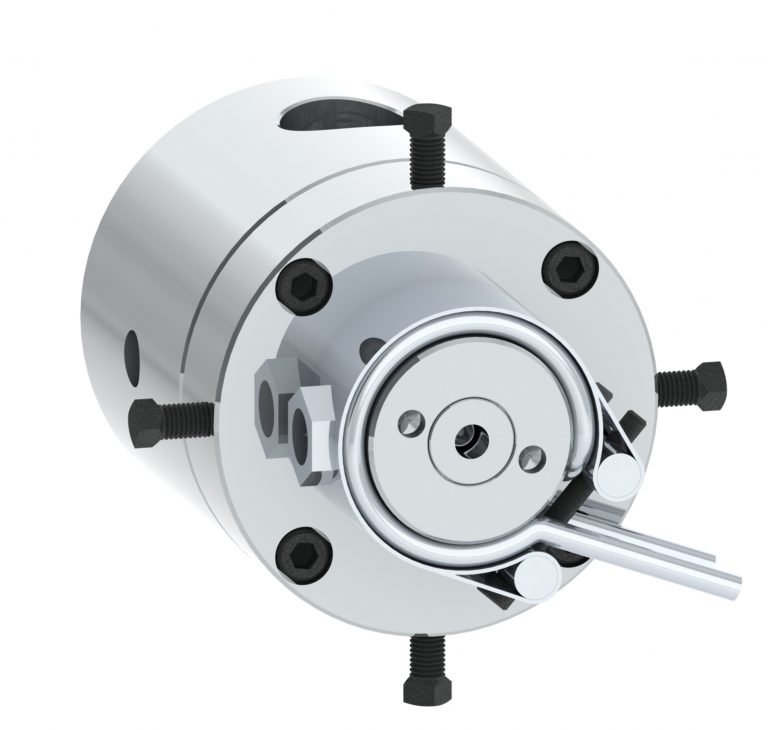

800 – Simple Crosshead

Our 800 Series crossheads can be configured to be fixed center or adjustable, featuring built in cartridge heaters, and a low volume split feed balanced flow.

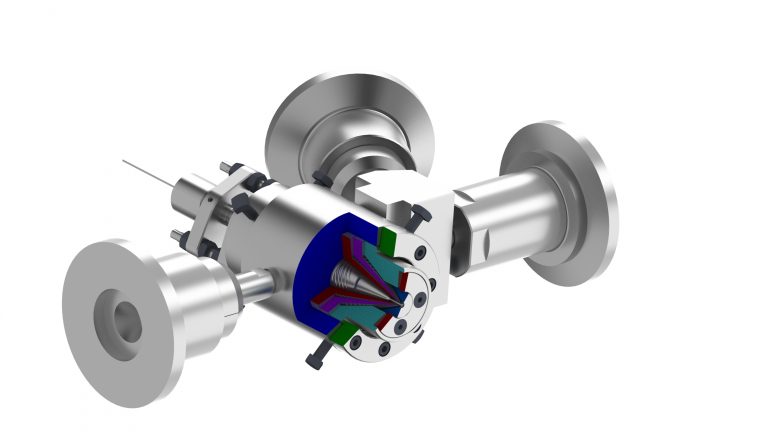

900 – Spiderless In-line

Our Spiderless Inline Heads offer simplicity and fewer parts with a low volume split balanced flow.

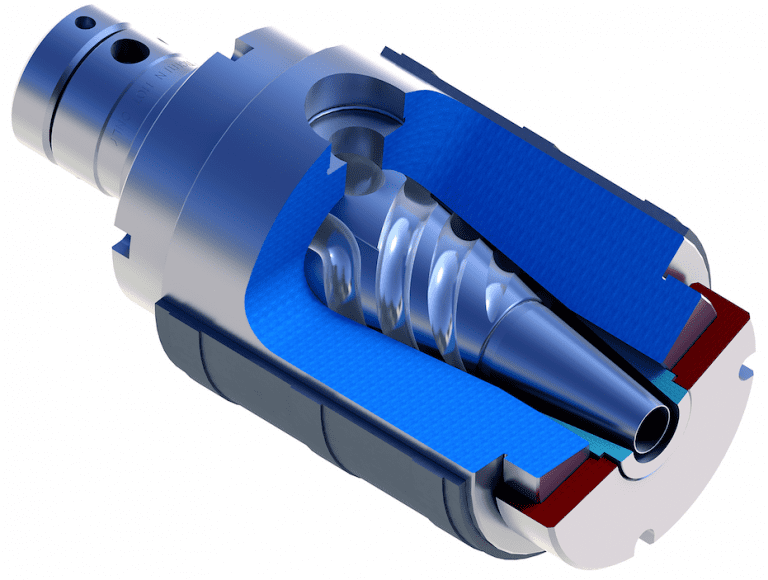

Bullet – Standard Crosshead

The Bullet™ was designed specifically by our engineers to expedite the production process and help our customers turn a higher profit. Featuring a multi-port spiral flow and fixed center design.

Extrusion Expertise Is Here For You

Options

Below are the many options available that contribute to our extensive line of tooling. The convenience of a variety of options gives us the flexibility to create the right tooling to help you produce even challenging End Products.

Configurations

Striping

© 2025 Guill Tool & Engineering Co. Inc.

Website design by Steers Studios. Website development by KatArt Graphics